FLUSH

Oil Flushing Services

FILTER

Electrostatic Oil Filtration

FILL

Non-Varnishing Fluids

Synthetic Turbine Fluid

OILKLEEN TURBINE FLUID-25 (TF-25)

Varnish build-up in Gas Turbine lube oil systems is the leading cause of unplanned shutdowns, system “trips”, and resulting in lost energy production. The root cause of these issues is the conventional petroleum-based turbine oil, which will oxidize through normal operation and form VARNISH and Sludge that cause servo valves to stick.

After 10+-years and over 100,000 hours of varnish-free performance, General Electric now includes PAG’s in their GEK 32568h specification for large frame gas turbines.

The OILKLEEN Non-Varnishing PAG-Based Synthetic turbine fluids are based off of many proven years of services with over 120+ Gas Turbines operating on PAG technology. It’s estimated by lab analysis and additive monitoring of many years in operation, that a Gas Turbine that converts to OILKLEEN Non-Varnishing PAG-based Synthetic turbine fluid can achieve 30+ years of service on a single charge of fluid. The OILKLEEN Non-Varnish PAG-base Synthetic turbine fluid is a combination of PolyAlkylene Glycol (PAG) base fluid and high-performance additive package which will not VARNISH.

When the OILKLEEN Non-Varnishing PAG-based Synthetic Turbine fluid is used, turbine bearings will typically operate at 5 degrees F to 10 degrees F lower temperature. This is due to the higher thermal conductivity of Group V PAG fluid versus Group I or Group II-IV oils.

OILKLEEN Non-Varnishing

PAG-based Synthetic Turbine Fluid

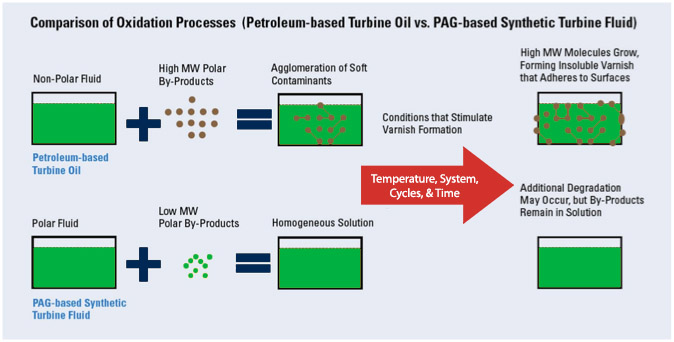

Why OILKLEEN PolyAlkylene Glycol (PAG) based Synthetic fluids don’t VARNISH?

Group V PolyAlkylene Glycol (PAG) base stocks are known to exhibit excellent thermal and oxidative stability as well as provide superior solubility characteristics as compared to Group I and Groups II-IV base oils. PAGs, by nature are relatively polar when compared with the relatively non- polar nature of Group I mineral oil, or with the increasingly non-polar Group II-IV base oils. Since PAG degradation compounds are polar, they will remain soluble and will not fall out of solution.

OILKLEEN Turbine Fluid 32 (TF-32)

The OILKLEEN Low-Varnishing Turbine Fluid 32 uses PAG-Based oil Modifier technology and combines with Group III Turbine Base oil and a high-performance additive package, to modify and change the polarity of the base oil and increase solvency of the petroleum-based oil to dissolve varnish build up and extend the life of the Turbine Fluid. The OILKLEEN Low-Varnishing Turbine Fluid with enhanced high-performance PAG additive package is a lower price point option with superior VARNISH removal and protection characterizes.

OILKLEEN RESTORE

OILKLEEN RESTORE is a high-performance base oil polarity modifier specifically designed for Petroleum-based oils that are experiencing VARNISH related issues or high MPC patch test results from lab analysis. OILKLEEN RESTORE will dramatically reduce varnish formation and RESTORE Severe levels of VARNISH shown on Varnish Potential ratings from the MPC patch test.

OILKLEEN RESTORE is not an antioxidant additive but instead modifies the polarity of the hydrocarbon BASE oil while dissolving VARNISH formation in the oil. OILKLEEN RESTORE is 100% soluble and compatible with all major commercial petroleum-based turbine oils and requires no FLUSHING or CONVERSION process to add. OILKLEEN RESTORE does increase the performance of the anti-oxidation additives in the oil and “Ruler” testing needs to be recalibrated to the new anti-oxidation levels. OILKLEEN RESTORE can increase the life of your Petroleum-based oil removing and preventing VARNISH related system failures or “TRIPS”.

OILKLEEN RESTORE

BASE OIL MODIFIER

- Shifts Polarity of the hydrocarbon base oil

- Dissolves VARNISH build up in System

- Reduces VARNISH MPC Patch Test

- Regenerates Anti-oxidation additive package

- Improves lubricity of the oil

- 100% compatible with all Major hydrocarbon Turbine Oils

- Requires NO CONVERSION process to add to Turbine Oil

Do you have VARNISH issues?

Contact OILKLEEN to see which VARNISH removal solution is right for you!